Closed-Loop Color Management in Paper Manufacturing

In the paper manufacturing process, there is significant value in managing color accuracy as far upstream as possible. When errors can be corrected as soon as they begin to occur, the result is less waste and a higher quality product.

Smurfit Kappa uses X-Rite solutions to avoid fluctuations in color and whiteness during paper production. Smurfit Kappa sets high standards for itself when it comes to quality, and the X-Rite system ensures these standards can be met.

Michael Bungenberg, Assistant Manager (Paper) |

Smurfit Kappa

X-Rite’s In-Line Color Measurement Systems span the entire paper manufacturing process, from laboratory measurement to pulp, wet sheet, and measurement before reel up. This ensures that color and shade remain constant throughout production. It also helps streamline the complexities of managing paper whiteness, especially when recycled pulp is added or optical brighteners are used.

To learn more about how you can revolutionize your paper manufacturing workflow, take a few minutes to watch this video, and then contact us [link] to discuss your requirements and the solutions we can offer to color-proof your business.

Managing the Color Workflow

From the lab through reel-up, an effective color measurement and management process will save time and money, and result in improved paper quality.

In the Lab

- Accurately determine colorant requirements

- Manage optical brightening agents with a UV-enabled color measurement instrument

- Speak the same color language as manufacturing, commercial printers and packaging converters

ERX30

The only color measurement instrument available for the laboratory that uses 45⁰/0⁰ geometry for alignment with closed-loop in-line measurement instruments on the paper machine.

Controlling Pulp Color in Real Time

- Continuous monitoring of pulp for real-time information about whiteness and/or color shifts to calculate expected color of finished paper

- Make immediate, even automated, adjustments in colorants and optical brightening agents to minimize waste

- Blend two lines of raw materials (e.g., dark and light) to a constant level

ERX40

Directly measures thick pulp (concentration 3% to 5%) through a bypass system.

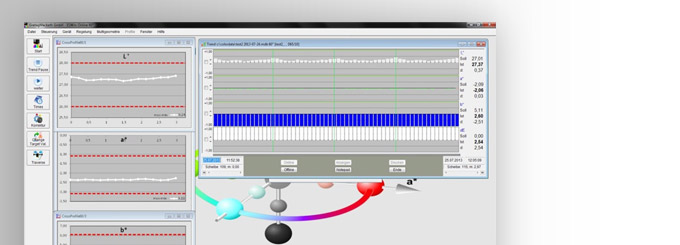

ESWin QC:

Software to quickly and easily control color measurement systems, including the ERX30, with easy-to-interpret graphic displays of color measurement results.

Color Measurement for Laminated Paper

- Gain accurate color measurement data without the need to wait for a laminated sample from the laboratory

- View color trend diagrams at a glance to determine if color shifts are occurring

- Efficiently comply with tight tolerance requirements for laminated products

ERX50:

Closed-loop inline control of color, opacity and optical brightening agents with the ability to make automatic adjustments when color drifts occur.

ESWin QC:

Software to quickly and easily control color measurement systems, including the ERX30, with easy-to-interpret graphic displays of color measurement results.

Color Measurement before Reel-Up

- Streamline the paper manufacturing process with shorter transition times, less waste, lower dyeing costs and less operator intervention for a fast return on investment

- Monitor color performance before reel-up as a final color quality control measure

- Control deviations from color target by automatically adjusting the amount of colorants or optical brighteners

ERX50

Closed-loop control of color, opacity and optical brightening agents with the ability to make automatic adjustments when color drifts occur.

ESWin CLCC:

Manages color quality on continuous process manufacturing lines, displays results and runs automatic in-line closed-loop color control for pulp manufacturing and other machinery.